Charge on the go: innovative clothing that converts heat into electricity

As wearable devices and the Internet of Things evolve, a sustainable solution for powering wireless devices and sensors becomes essential. Thermoelectric generators that convert waste heat into electricity can be used. A research team led by Masakazu Nakamura of the Nara Institute of Science and Technology (NAIST), Japan, is working on flexible, wearable thermoelectric generators. This is done with the help of carbon nanotubes (CNTs) that are sewn into the fabric.

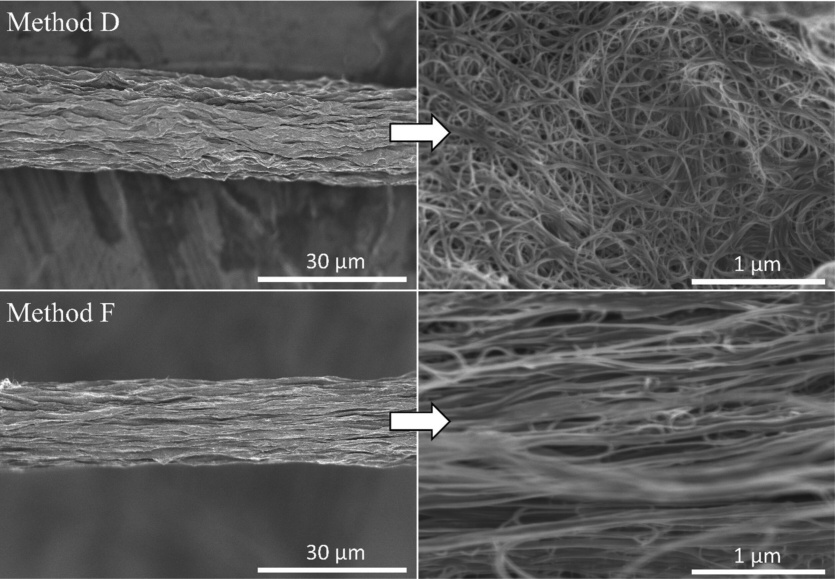

Effective thermoelectric materials create a voltage due to temperature differences. Carbon nanotubes meet most of the necessary requirements. Their flexibility and high mechanical strength also make them a promising application. However, the high thermal conductivity of CNTs limits their thermoelectric performance. To reduce thermal conductivity, the tubes are dispersed in a solution and combined with other materials. The resulting material is used to create yarns through the wet spinning process. However, conventional dispersion methods often entangle nanometer-thick filaments, which reduces their electrical conductivity and thermoelectric performance.

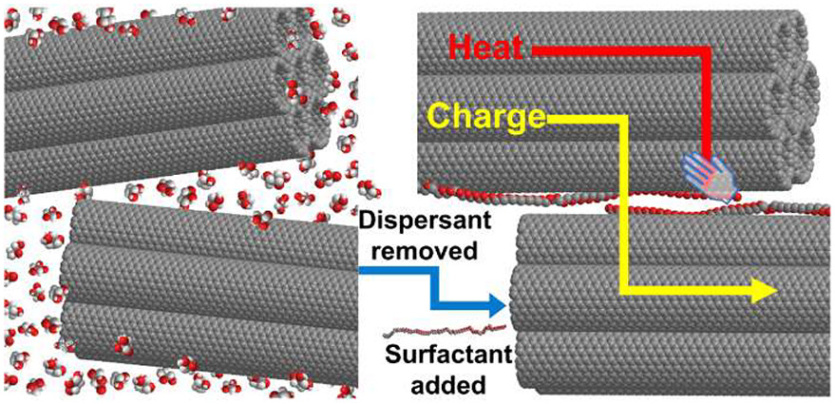

In a study published in ACS Applied Nano Materials, Nakamura, along with graduate student An N. Nguyen and other NAIST representatives developed a new method of dispersing CNTs. By using glycerin as a dispersant and polyoxyethylene(50) stearyl ether as a surfactant (used to improve the spreading and wetting properties of the liquid), the researchers have produced a fabric that is acceptable for use.

“We are introducing a low-cost, fast, and environmentally friendly method for developing flexible, wearable fabric-type thermoelectric devices,” Nakamura says.

Glycerin has a high viscosity, which makes it an excellent medium for uniform dispersion, and the surfactant prevents the accumulation of CNTs in the dispersion. Surfactants with oxyethylene groups also prevent heat transfer.

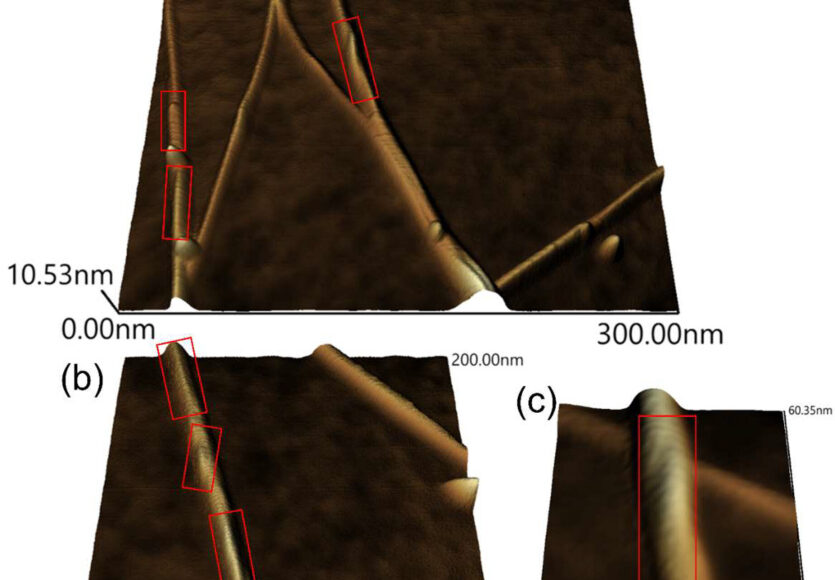

The concentration of the surfactant is crucial because it affects both the thermal and electrical conductivity of the dispersion. The process, which took only three hours and used environmentally friendly chemicals, produced a CNT yarn with well-aligned 8 nm diameter bundles with surfactant in between. The alignment of CNTs usually increases both electrical and thermal conductivity. However, by placing surfactant molecules between the beams, the researchers were able to suppress heat transfer. Thus, the proposed new approach is promising for improving the thermoelectric characteristics of carbon nanotubes and materials made of them, from filaments to films and bulk structures.