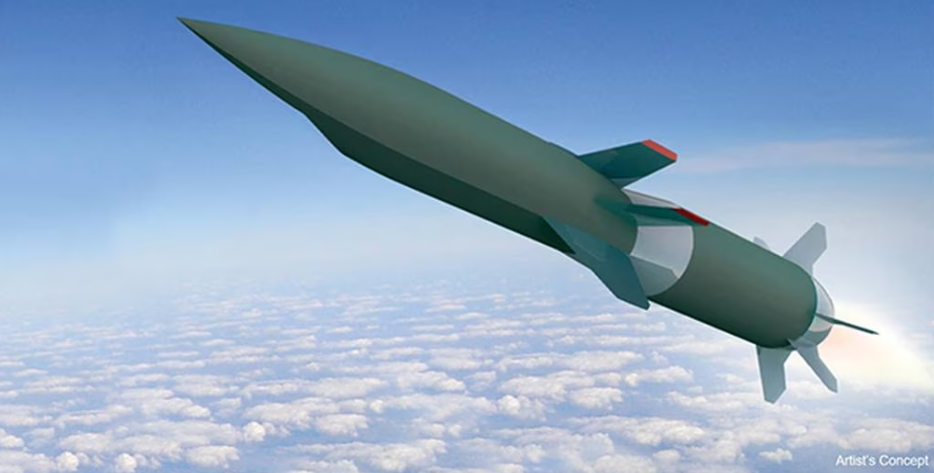

Printing an engine for a hypersonic rocket is easier and opens up “fantastic possibilities,” the US says

Additive technologies open up new opportunities for arms and military equipment manufacturers

The United States is actively working to integrate 3D printing technologies into its defense sector, as these capabilities can be extremely effective in facilitating the work of both the military and weapons manufacturers, changing the rules of the game on the battlefield.

Additive manufacturing makes it possible to create a number of necessary components for weapons and military equipment, up to such modern weapons as hypersonic missiles, according to Keith DeVries, a representative of the US Department of Defense, Deputy Program Manager for Manufacturing Technology, as cited by Defense News.

According to him, today 3D printing technologies have advanced significantly compared to previous years and now they provide new opportunities in the creation of weapons and components for them.

Additive technologies can be especially effective in the development of new weapons, where new complex components need to be created, and 3D printing allows this to be done faster than traditional technologies.

Hypersonic rockets are cited as an example – their direct-flow jet engines require the production of complex chambers that can literally be printed on a printer – which will be easier and faster, and opens up “some fantastic opportunities for manufacturers,” as DeVries assures.

For example, the printer allows engine components to be printed without complex welded and soldered joints, which saves time required for testing. But at the same time, DeVries believes that traditional technologies should not be abandoned either, and that they should be replaced by 3D printing “in a frankly limited way” and used “exactly where it is needed and where it brings the most benefit.”

In general, developers around the world are now actively using additive technologies to build rocket engines. For example, in 2021, Pratt & Whitney said that they wanted to make the TJ-150 engine exclusively from 3D-printed parts.

At the same time, NASA launched a test rocket in May of this year, all the parts of which were printed on a printer, which will eventually allow manufacturers to reduce the cost of production.

At the same time, 3D printing for military purposes is also used for simpler things, such as manufacturing parts for unmanned aerial vehicles, which is actively used by the Armed Forces of Ukraine today.

And the British company Babcock is actively developing the idea of “advanced units” that could print the parts necessary for a particular weapon directly on the battlefield to simplify the maintenance of weapons on the battlefield.