BAE Systems presents new technology for mass production of artillery ammunition

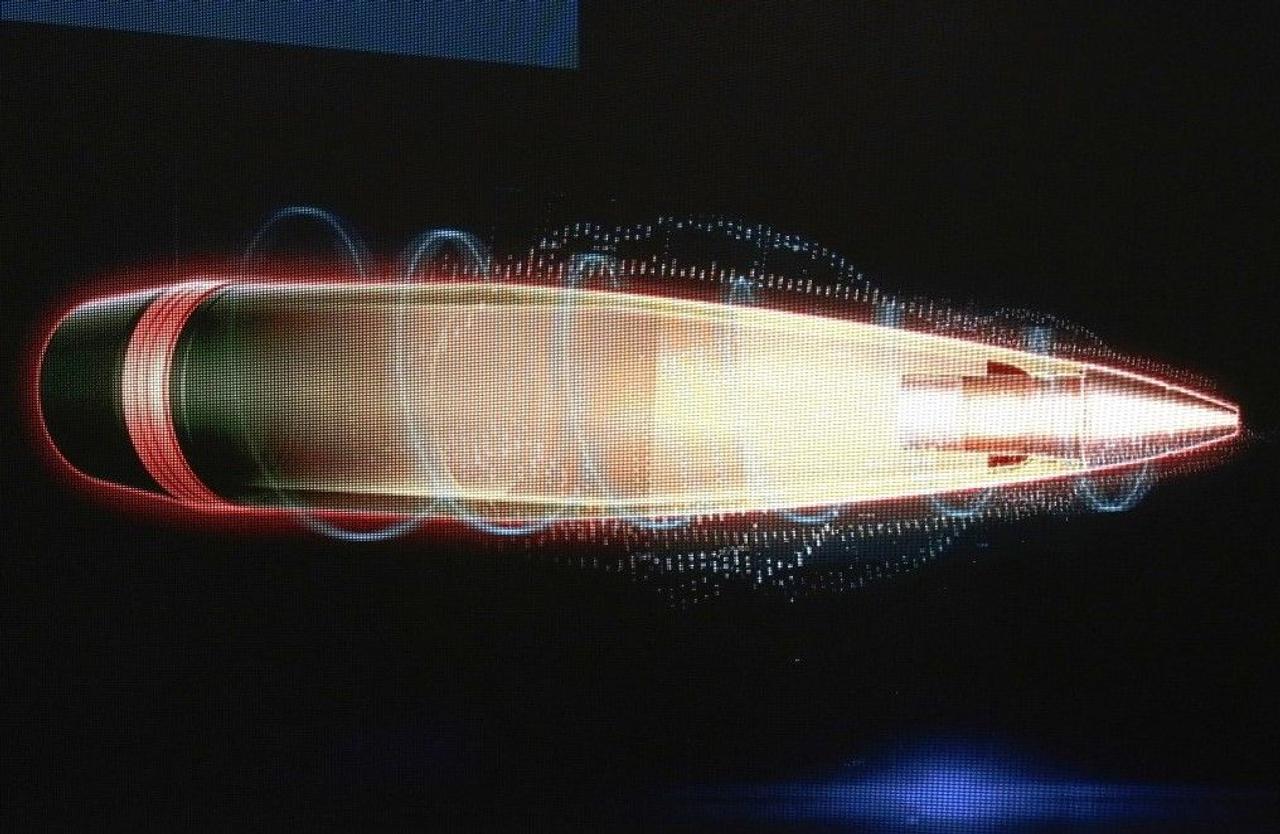

Defense concern BAE Systems has introduced a new technology for the manufacture of artillery ammunition that will simplify and speed up the production process. The new generation of NGAA artillery ammunition is intended to solve the key problem of cost and mass production.

The current production problems should be solved by a comprehensive approach that focuses on the use of less specialized materials already used in civilian industry and not related to the defense sector.

This will allow the use of existing civilian enterprises for mass production of ammunition when the need arises, and will also include defense production in the civilian supply chain.

“We will produce the ammunition body from industrial steel grades, moving away from the specialized raw materials that have been used until now. This will allow us to buy it from a much larger number of suppliers,” explained BAE Systems representatives.

BAE Systems engineers use heat treatment to maximize the characteristics of steel used in the production of ammunition.

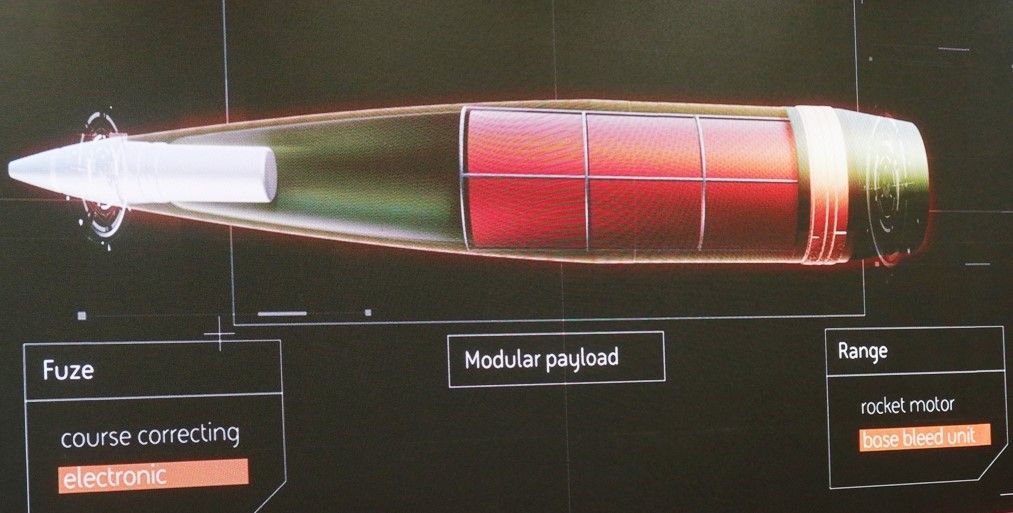

In addition, NGAA ammunition has a one-piece body, which will greatly facilitate the production of current models with a multi-part body.

The new production technology has also been innovated in terms of the process of filling the case with explosives. Instead of the classical injection molding of plasticized explosives into the casing, the concern’s engineers want to use the technology of “resonant acoustic mixing.” The new method should shorten the process from hours to minutes while reducing costs and waste.

NGAA ammunition will be equipped with the revolutionary e-Fuze fully electronic fuze detonator, replacing the old mechanical analogues.

Competitiveness is a key issue, so BAE Systems aims to reduce the cost of producing one munition by up to 75% using the new technology.