One of the problems associated with lunar missions is fine dust or regolith. Once in a low-gravity environment, tiny charged particles hang in space and pose a serious danger to the operation of Earth’s mechanisms. New research has shown that regolith can be turned into smooth roads by directing a laser at it. The strength of the material will be comparable to concrete. Such roads could become useful infrastructure for future lunar missions.

Scientists in the European Space Agency’s (ESA) PAVER project decided to find out whether materials available on the Moon could be used to build roads. They suggested using a lens to focus sunlight. This would create a beam hot enough to melt moon dust. The result would be tiles that could be used to pave a road. The process of creating a solid mass from small particles using pressure or heat without liquefying the material is called sintering.

The experiments were conducted using a fine gray powdery dust called EAC-1A. This is a simulator of lunar regolith developed by ESA – a mixture of minerals in the same proportions as they occur on the Moon.

The scientists used a CO2 laser in the experiment, a type of laser in which an electric current passes through carbon dioxide, creating a light beam with a diameter of 45 millimeters.

The experiment was successful. By pointing a laser at an artificial lunar regolith, the researchers created “tiles” of lunar dust with a diameter of 25 cm. The power of the laser corresponded to the indicator that could be achieved with the help of sunlight on the Moon. It would require only moon dust and a 2.37-square-meter Fresnel lens. m to focus the sunlight available there.

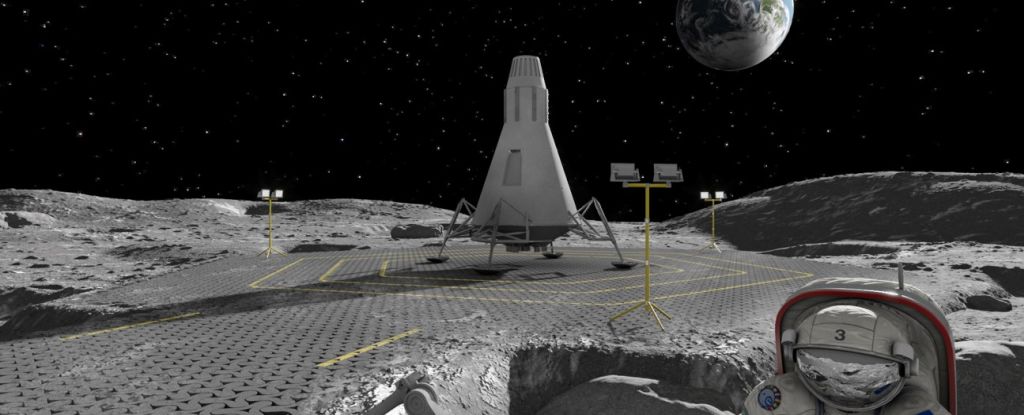

The researchers also tested the strength of the tiles, considering that the lunar equipment is likely to be heavy. They found that the sintered material has strength comparable to concrete. The tiles are suitable for creating paved roads and landing sites on the Moon. Thanks to their production, the amount of harmful dust above the lunar surface, which threatens to damage equipment and clog fragile mechanisms, will decrease.

The next step will be to improve the strength of the material. Despite the strength already achieved, there were still cases of breakage, possibly due to microscopic defects. Reducing these defects will make the lunar road more reliable.