In the world of robotics, the speed of development of 3D printing technologies is growing every year. Researchers at ETH Zurich, together with Inkbit, have proposed a new technology that allows printing robots with bones, tendons, and ligaments using new strong and flexible polymers.

The advantages of slow polymer

Previously, 3D printing was limited to high-speed polymers that cure quickly. However, the new technology makes it possible to use polymers that harden more slowly and have improved elastic properties, which are stronger and more stable. This makes them ideal for printing robot components such as bones, tendons, and ligaments.

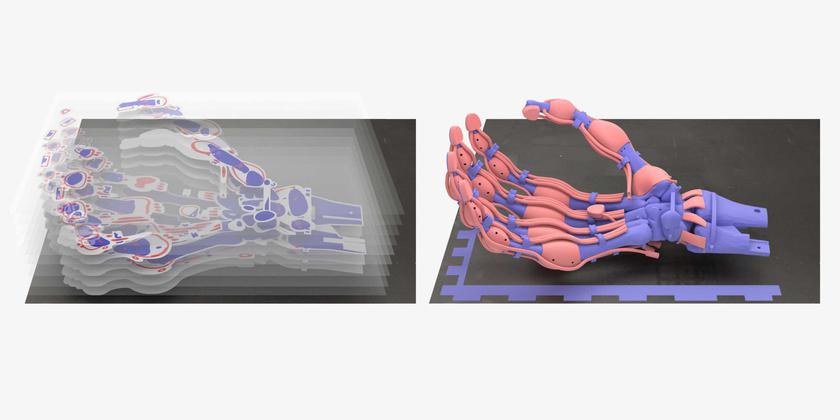

The technology of the printed hand

Thanks to a new technology developed at ETH Zurich and MIT, printed robots with bones, tendons, and ligaments are now possible. Scientists can now print complex structures using different materials at the same time. At the same time, the new technology allows you to combine soft, elastic and rigid materials in one robot. In addition, researchers can create very fine structures and parts using this technology.

One of the main obstacles in printing with slow-curing polymers was the need to scrape the surface after each layer. But thanks to the 3D laser scanner added to the printing technology, each printing layer is instantly checked for surface irregularities. This way, it is possible to avoid bumps without scraping.

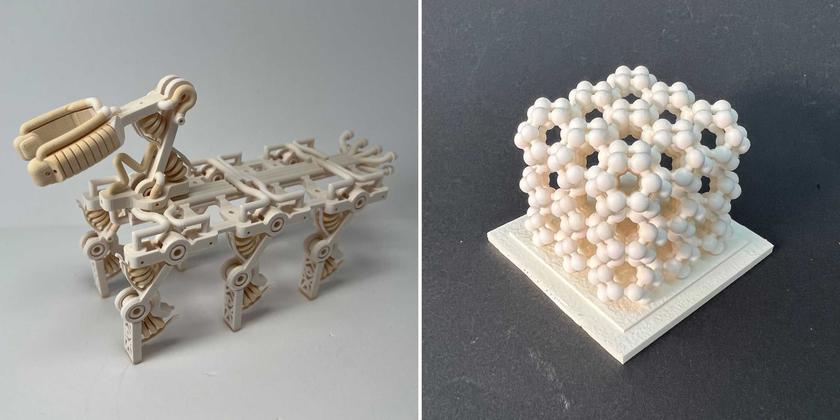

Other examples of 3D printing

The application of 3D printing is expanding to various industries. In addition to printed robot arms, scientists are also developing robot legs using this technology. In addition, 3D printing is used to create metamaterials that can absorb vibrations.

The experiment with a printed hand with bones, tendons, and ligaments is a breakthrough in the development of robotics. The use of slow-curing polymers in combination with 3D printing allows for the creation of more durable and robust robots. This opens up new opportunities in the development of new structures and additional applications for robots.