A 600-meter building was printed on a 3D printer in Germany in 140 hours (photo)

The Wave House team has built a new data center in Germany using the power of 3D printing technology to bring a sense of style to cloud computing infrastructure, creating Europe’s largest 3D printed building.

The Wave House building is located in Heidelberg, designed by SSV and Mense Korte and created by Peri 3D Construction for the developer KrausGruppe. Its area is 600 square meters. m. As already mentioned, its unusual appearance was the result of an attempt to revitalize a rather boring building.

“Due to the lack of windows and large openings in the main areas of the data center for security reasons, data centers tend to look quite dull and boring. As long as these centers are located far outside of cities, this is less of a concern, but the trend to bring these centers closer to users and locate them in suburban areas has created a need to make data centers more visually appealing,” explains COBOD.

The architects solved the problem by giving the walls a wave-like design, a design feature that also gave the building its name: “Wave House”. Walls with a wave-like design could not be realized using traditional construction methods, so 3D printing construction technology was used because of the freedom of design.

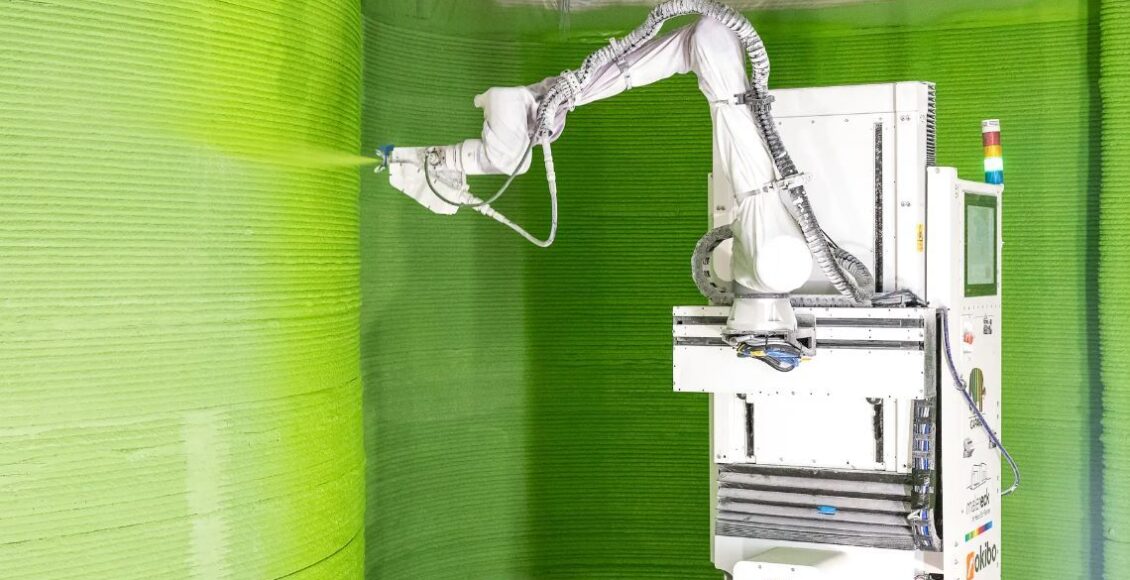

The construction process was similar to other 3D printed architectural projects, with the 3D printer extruding recyclable cement-like mixture from the nozzle in layers at a rate of 4 square meters per hour to form the 54-meter-long, 11-meter-wide, 9-meter-high exterior walls.

The printing process took about 140 hours. After that, people put the finishing touches on the project, including the roof and doors, lighting, wiring, and equipment needed for a modern, internet-connected data center. However, a robot painter from Deutsche Amphibolin-Werke was used to paint the interior.

According to the Kraus Group, the construction process using 3D printing resulted in significantly lower CO2 emissions than using traditional methods. The entire project from design to commissioning, including the work of robots and humans, took 6 months.