Japan has successfully tested a jet engine that runs on cow dung

The Japanese company Interstellar Technologies (IST) has completed static fire tests of its ZERO liquid biomethane jet engine. The tests demonstrated the potential of biomethane derived from cow manure as an environmentally friendly rocket fuel.

To achieve excellent performance, the ZERO combustion chamber has undergone extensive research and development in collaboration with the University of Tokyo and JAXA. This led to design improvements that reduced the cost of producing the rocket engine, which is estimated to be half of the total cost.

The tests will help IST move forward with the development and production of a 130 kN class operational model based on the knowledge gained from the design, production, and testing of the 60 kN class model.

ZERO is a satellite launch vehicle designed to meet the demand for small satellites. In response to global demand, ZERO is expanding its capabilities to launch satellites weighing up to 800 kilograms into low Earth orbit. ZERO has a length of 32 meters, a diameter of 2.3 meters and a total weight of 71 tons.

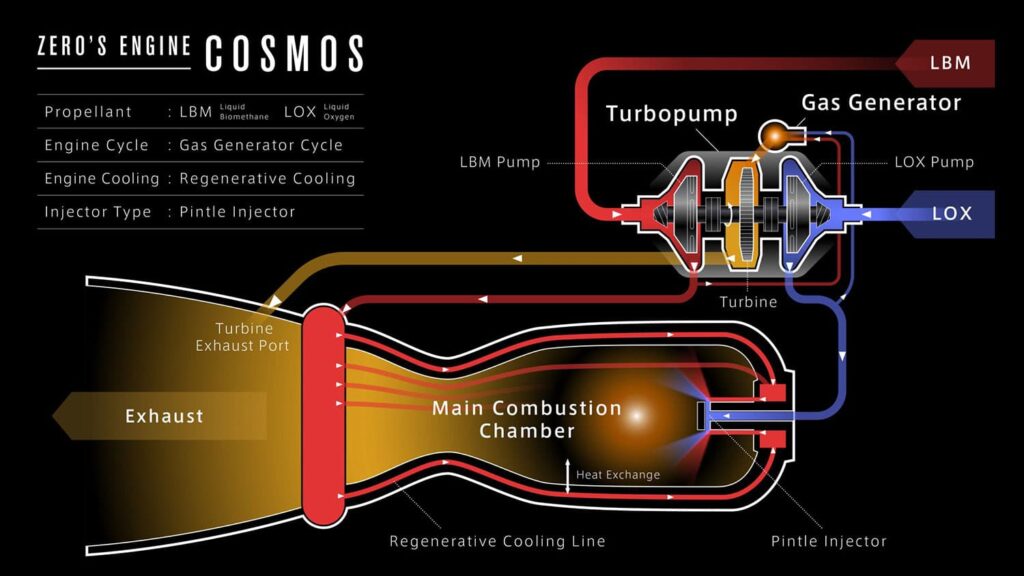

The rocket engine is liquid-fueled, using LBM as fuel and liquid oxygen as an oxidizer. For the first time, IST introduced a gas generator cycle, which involves burning part of the fuel in a gas generator to drive a turbopump at tens of thousands of revolutions per minute and supply fuel to the combustion chamber under high pressure.

The rocket has a two-stage design and a needle injector, which reduces the number of components and increases combustion efficiency. The needle nozzle delivers fuel (liquid fuel and oxidizer) in a controlled manner to the combustion chamber of the rocket engine.

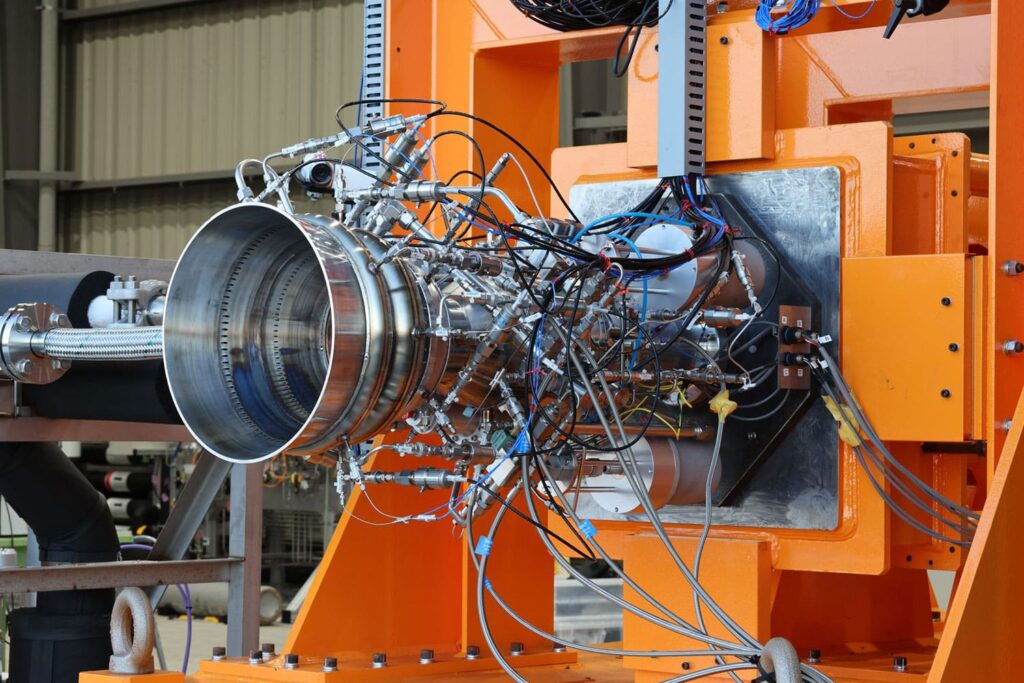

The regenerative cooling system also efficiently uses fuel to cool the walls of the combustion chamber. The combustion chamber, turbine pump and gas generator have been tested, and their integration is planned for the future.

Liquid methane has become the preferred fuel choice for rocket launches due to its advantages, such as fuel performance, price, availability, ease of handling and environmental impact. Air Water Group is making efforts to create a closed supply chain for liquid biogas-methane (LBM), which is produced by processing methane from biogas derived from livestock manure in the Tokachi region of Hokkaido.

The LBM used in the tests is carried out by separating and purifying methane, the main component of biogas, and then liquefying it at a temperature of approximately -160°C. It is striking that it reaches such a high level of purity, comparable to that of conventional rocket fuel.